Making and milling, in the beginning glimpse, seem to be quite similar procedures and achieve same exact results. Therefore, what is the difference – and why do some in us offer both processes? This type of was among things that confused myself in quick my own career at Aldermans. While a lot of of our own customers knows the answer, others may discover this an excellent regarding what are the results behind those times in the wonderful world of metallic fabrication!

Computer numerical controlmachining

Often making and milling are generically called "CNC machining"– companies often request CNC engineering for turning or milling by just name. Needless to say, it 's the work to make sure that the almost all appropriate process may be used each and every time.

Put simply, the big difference between the two processes comes down to which part goes– generally speaking terms, the metal or maybe the machine.

With COMPUTER NUMERICAL CONTROL turning a metal bar is normally fed in the lathe and revolves at speed while 1- point cutting tool removes portions in the metal to generate the required shape.

With milling the metal usually continues to be still while multi- stage cutting tools rotate around this.

Turningvs milling- COMPUTER NUMERICAL CONTROL engineering

Turning

Items processed simply by a lathe will be cylindrical and must be on-- centre. Turned parts may range coming from simple rings to complex bent components. CNC turning is among the best way to mass- create these types of parts.

Numerous cutting tools can be set up within the lathe tooling mind( pictured below) to do different trimming functions sequentially, to create parts on a one- pass procedure. Straight cuts, tapers and curves can all be created simply by varying the angle and interesting depth of the cut.

Lathe tooling head- CNC turning

These types of pictures below show a bar stock being turned on the lathe( fixed in to the turret), and the finished result, where straight and tapered turning continues to be used.

Barstock on lathe turret gun

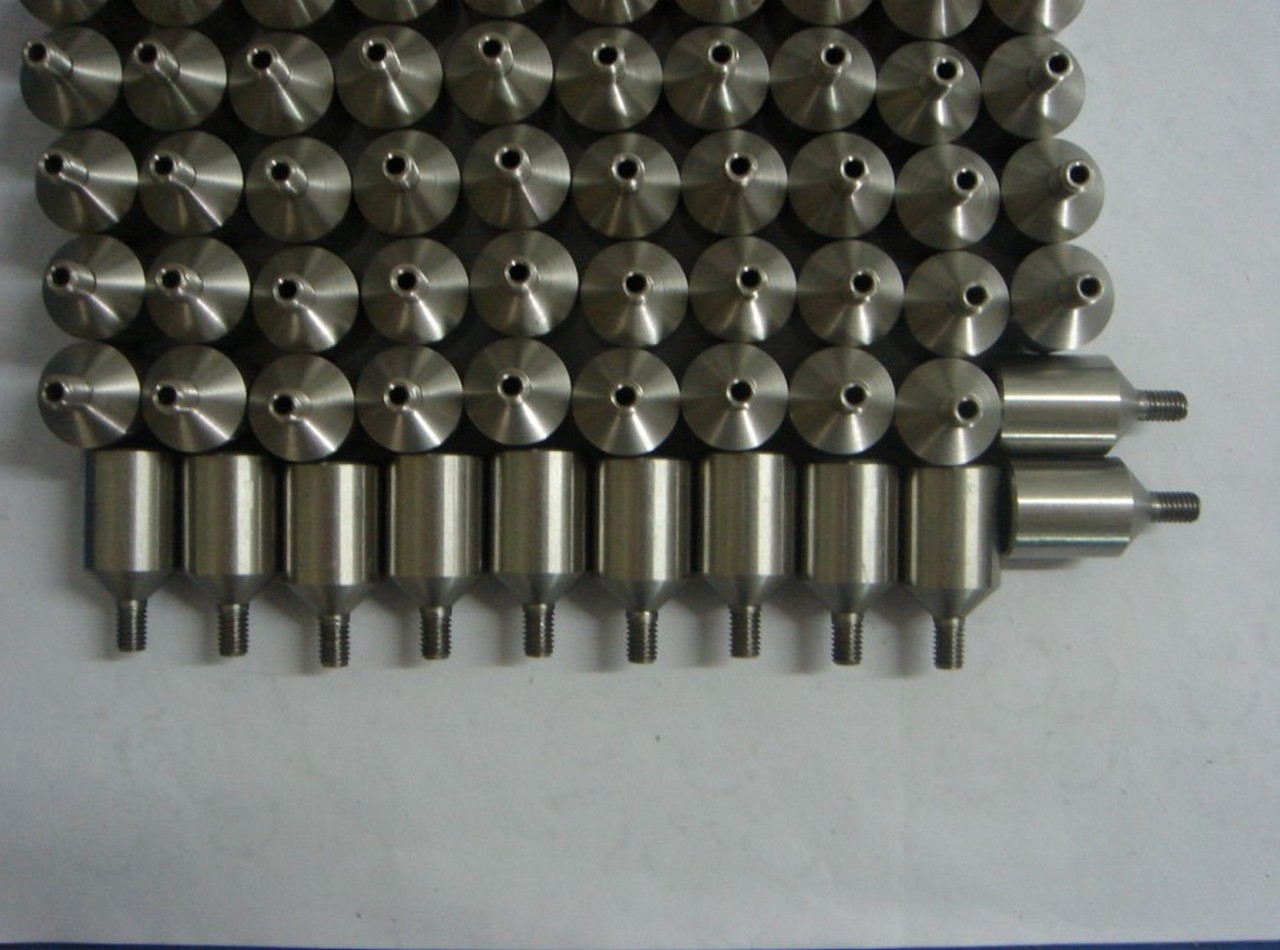

Switchedbillets

Watch our video in CNC submiting action, beneath:

Milling

Milled parts are not really necessarily cylindrical. Milling machines make use of multi- point cutting equipment, and there may be more than 1 tool working on the part at a time . Milling might be the desired choice in the event that the part needs anything which usually can be off- center or angled( such as openings or cuts), or for supplementary features including indentations or bands.

Here are two pictures in milling in action, in which the component is being drilled.

Milling-- drilling

Milling- drilling

The photographsmilky- white fluid confirmed in the images is trimming fluid, which provides for a good coolant and lubricant. At Aldermans we use a water-- based emulsion in all the turning and milling processes.

Milling to shave material from the top workpiece simply using a tooling head with multiple cutters( plain milling or simply face milling), or to convey its edges with a good cutting tool using a line( profile milling or side milling)– examples proven below.