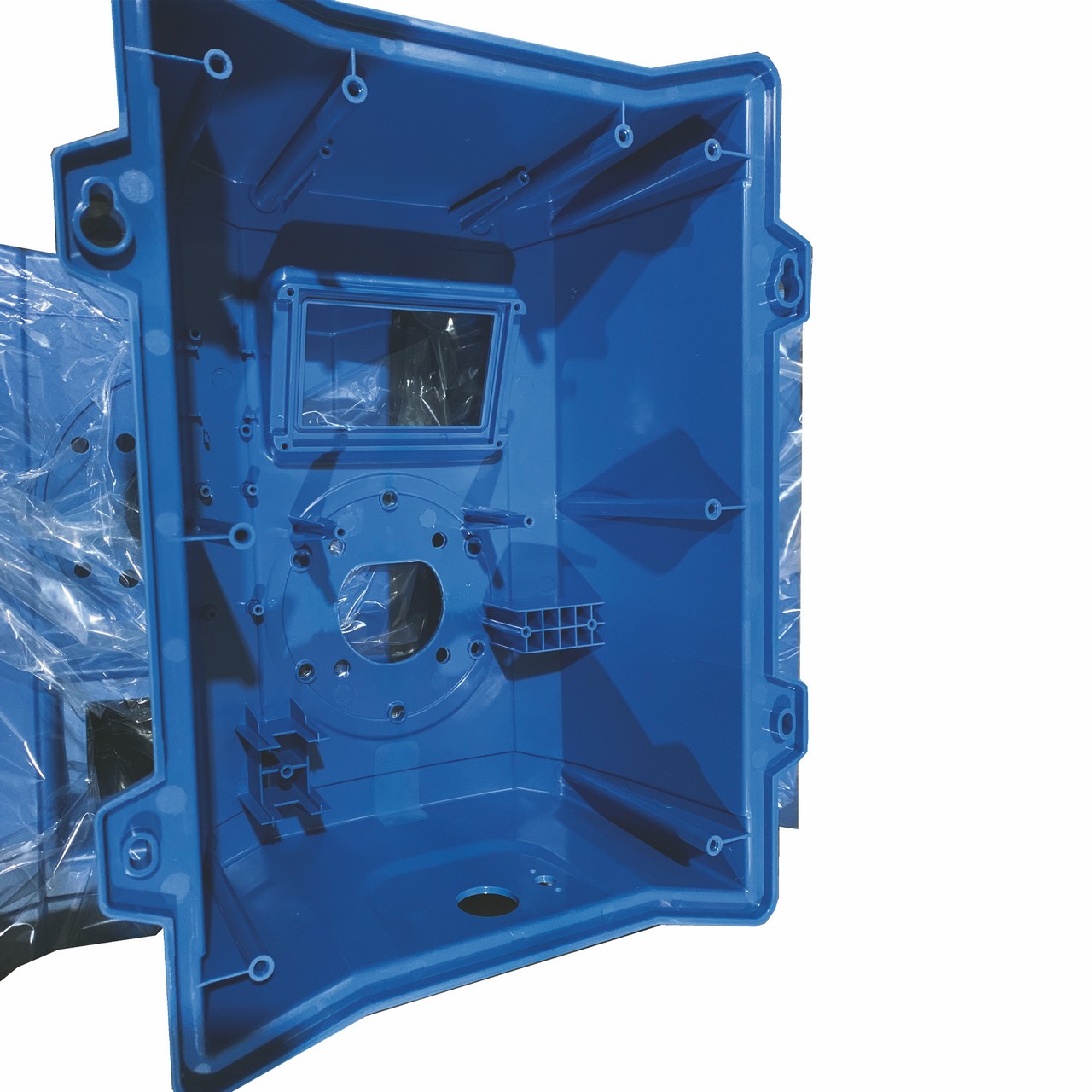

Pieces of an Injection Mould

So you've designed a product. You might have gone through the RFQ process, revealing your CAD images with engineers who probably made even more tweaks. Typically the business is proceeding to be made of plastic using the injection creating process. But you might have never made a plastic injected part before. There are countless new words and keyword phrases being tossed around so you don't really know very well what they all mean.

Can be a tool the same thing as a mould? Why is mould spelled two ways (mold vs. mould)?

And just how does the whole thing actually work?

No one would blame you for buying glossary of phrases right about now. Include no fear. Listed below, we tenderize the components of an injection mold in simple, easy-to-understand dialect. It even includes labeled cutaway images. I promise, if you didn't understand how a picture mold worked before, you will after reading this.

PIECES OF A PICTURE MOLD

An injections mold is a tool made up of a series of elements that enables molten plastic-type material to be produced and cooled in such a way about create a discrete part condition.

DETAILED PIECES

GRIP PLATES

Mold halves are placed on the molding platens by the clamp china. Mold clamps use large can be bolted on to hold them in place; other machines hold the mould onto the platen with magnets.

NOZZLE/SPRUE BUSHING

Liquified plastic-type material is pushed through the nozzle of the barrel of the molding machine. The nozzle car seats against a surface on the mould the sprue bushing and locating diamond ring, that really help center the nozzle to the mold.

FEED METHOD

Plastic flows through the sprue bushing in a sprue, then to personal runners which take the material to the gates - the access point of the stuff to the personal cavities.

The sprue and runners can be reground (chopped up) and used again. They can be eliminated by by using a hot runner system.

SPACE

Cavities are aspects of the mould where part is formed into desired shape. Molds must be balanced, so there are normally only a certain variety of cavitations allowed (1, 2, 4, 6, etc... )

AIR CONDITIONING

Plastic is being injected hot and is cooled by cooling down channels that allow conduction to cool the business. Functioning fluid is usually normal water, although oil can be used in high temp apps.

GUIDE PILLARS/BUSHINGS

Tooth cavity and core mould halves are covered by insurance to be in proper alignment during mold close to the use of guide pins (or pillars) and guide bushing (or sleeves).

EJECTOR SYSTEM

Parts are pushed off of the core by using a series of buy-ins or bars. These kinds of series are called the Ejector Method.

EJECTOR PLATE METHOD

The ejector buy-ins are mounted in an ejector menu. The motion of the ejector menu forward allows the pins to move forward, pushing the part off of the main. The ejector holding onto plate holds the pins to the ejector plate.