COMPUTER NUMERICAL CONTROL Machining: A Specialized Definition

If you have ever watched a good episode of Exactly how It's Made, a person probably have a few idea how lathes along with other metal operating machines function.

Because technology has enhanced through the years, it created a higher precision pc controlled manufacturing method we all know as COMPUTER NUMERICAL CONTROL machining.

CNC devices (computer numerically managed machines) are electronica mechanical devices that will can manipulate equipment around a different number of responsable, usually three or even five with higher precision per training from a pc program.

The 1st CNC machines had been developed in the particular 1940s and 50s and relied mainly on a information storage technique referred to as punched tape. The particular code to manage the machines might be manually smacked into a information card and given into a program that could then translate the information.

Needless in order to say, these earlier machines were awkward and their features was limited.

COMPUTER NUMERICAL CONTROL machining technologies quickly grew as technical capability only more rapid back in the particular 20th century, which usually brings us in order to how modern COMPUTER NUMERICAL CONTROL machines work.

Exactly how CNC Manufacturing Functions: Subtractive Machining

COMPUTER NUMERICAL CONTROL machining is 1 of 2 various ways that technicians or manufacturers may generate a bodily part from the pc aided design (CAD) file, using the some other being 3D publishing known as ingredient manufacturing.

The comparison between these 2 techniques is kampfstark. CNC machining such as other machining procedures is really a subtractive procedure where material will be taken off a share. 3D printing, upon the other hands, is an ingredient process essentially working in reverse.

COMPUTER NUMERICAL CONTROL Before CAD Abilities

Machining is the way to change a stock item of material this kind of as aluminum, metal or titanium right into a finished product or even part.

CNC devices rely on electronic instructions, specifically known to as G-code before modern computer-aided manufacturing and computer-aided design programs, like Autodesk's Fusion fish hunter 360 were around, machinists would manually create down thier G-code to control these types of machines.

CAD (computer aided design) applications today allow an individual to require a 3D IMAGES and automatically crank out G-code that can travel the machine having little input.

As soon as comparing the functionality of automated COMPUTER NUMERICAL CONTROL machining to typically the manual alternative just like lathes and also other engineering techniques, you could start to be able to see the positive aspects.

CNC machines easily improve your swiftness at higher finely-detailed and accuracy even though simultaneously allowing typically the transformation of some sort of digital design in a physical aspect. CNC machines happen to be precise and so are sized in a huge number of a inch.

Standard engineering can provide tolerances on parts all around plus or less 0. 005 inches wide.

Fine machining is going to produce tolerances involving about plus or perhaps minus 0. 001 inches

Specialized functions like polishing can easily offer up repeatable tolerances as small as plus or perhaps minus 0. 00005 inches.

For referrals, a human frizzy hair is. 00069 inches wide thick.

pexels-cottonbro-7480242

COMPUTER NUMERICAL CONTROL Machines: Models together with Functionality

Now of which we have the essentials of CNC engineering out of typically the way, we can easily commence to dig in its intricacies. Quite a few designs or certain machining processes demand the use involving multiple tools to be able to make cuts. A person tool doesn't purpose universally.

Because of this, machinists will often build up digital tool your local library that interface while using physical CNC equipment. These machines, typically costing hundreds involving thousands of us dollars, can automatically transition tooling when guided by their electronic digital instructions, allowing to get those to become making workhorses.

3-Axis together with 5-Axis Mobility to get CNC Machines

Standard CNC machining is going to move one or perhaps two axes labelled as the X-axis along with the Y-axis. You'll typically hear the terminology. 2. 5 axis, 3-axis and 5-axis CNC machines, which will simply refer to be able to the degrees involving freedom a equipment can make slices in.

A 3-axis machine will relocate the X, Sumado a, and Z axis. Whereas a 5-axis machine can relocate these three responsable along with a couple of additional rotational responsable.

As you could be able to be able to imagine, the probabilities having 5-axis machines happen to be practically endless.

5-axis machines once was relegated to superior do the job, but as they may have become more cost-effective they are really quickly growing to be standard in quite a few shops.

Three COMPUTER NUMERICAL CONTROL Machining Tools: Soccer drills for kids, Lathes, and Milling

There are several conventional machining solutions that you will need to understand to seize the basics involving how material can be removed from inventory in CNC equipment.

CNC Drilling

Soccer drills for kids work by rewriting a drill tad and moving somewhat into contact having a stationary inventory.

CNC Lathes

Lathes function in change to drilling. Lathes spin the prohibit of material in opposition to a stationary punch bit or used vinyl cutter to remove product in a very circular or perhaps fluid path. Typically the shape capabilities in lathes are usually more constrained than other tactics, but modern technological innovation does allow these kinds of machines to develop things such like square holes or perhaps non-circular shapes.

COMPUTER NUMERICAL CONTROL Milling Machines

Typically the most common COMPUTER NUMERICAL CONTROL machine type is called a milling equipment. Milling machines entail the use involving rotary cutting resources to remove product from a inventory piece. These equipment function similar to be able to drills with the pedaling capabilities encompassing significantly more variety.

Virtually any material can possibly be used in COMPUTER NUMERICAL CONTROL machines from clear plastic to titanium. Several materials will range properties, so machinists and engineers is going to overcome their one of a kind challenges by adjusting machining variables just like tool selection, RPM, feed rate, together with coolant flow between a substantial variety involving other factors.

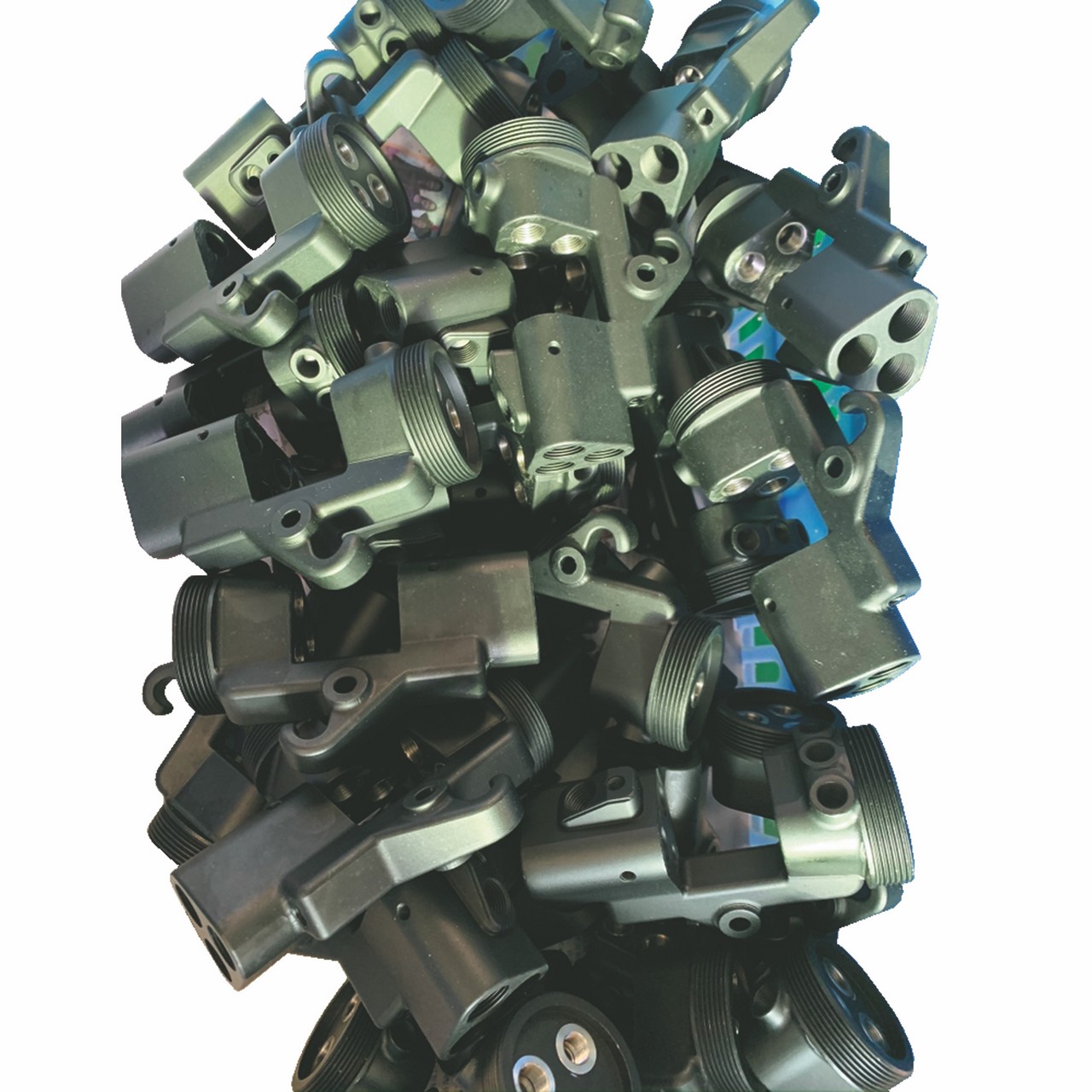

cnc-milling-machines

CNC Machining’s Endurance

CNC machined pieces are usually around an individual. They hold along your car together with perform vital capabilities aboard SpaceX rockets. CNC machining is possibly the only approach to produce superior metal parts to get engineering designs throughout the world.

CNC machining is possibly the most important manufacturing procedure of typically the 21st century and it is functionality drives scientific advancement across typically the globe. It is deal that is maintaining the growth involving technology and machinists along the planet happen to be changing the earth with their COMPUTER NUMERICAL CONTROL machining skills.