What exactly is CNC Machining?

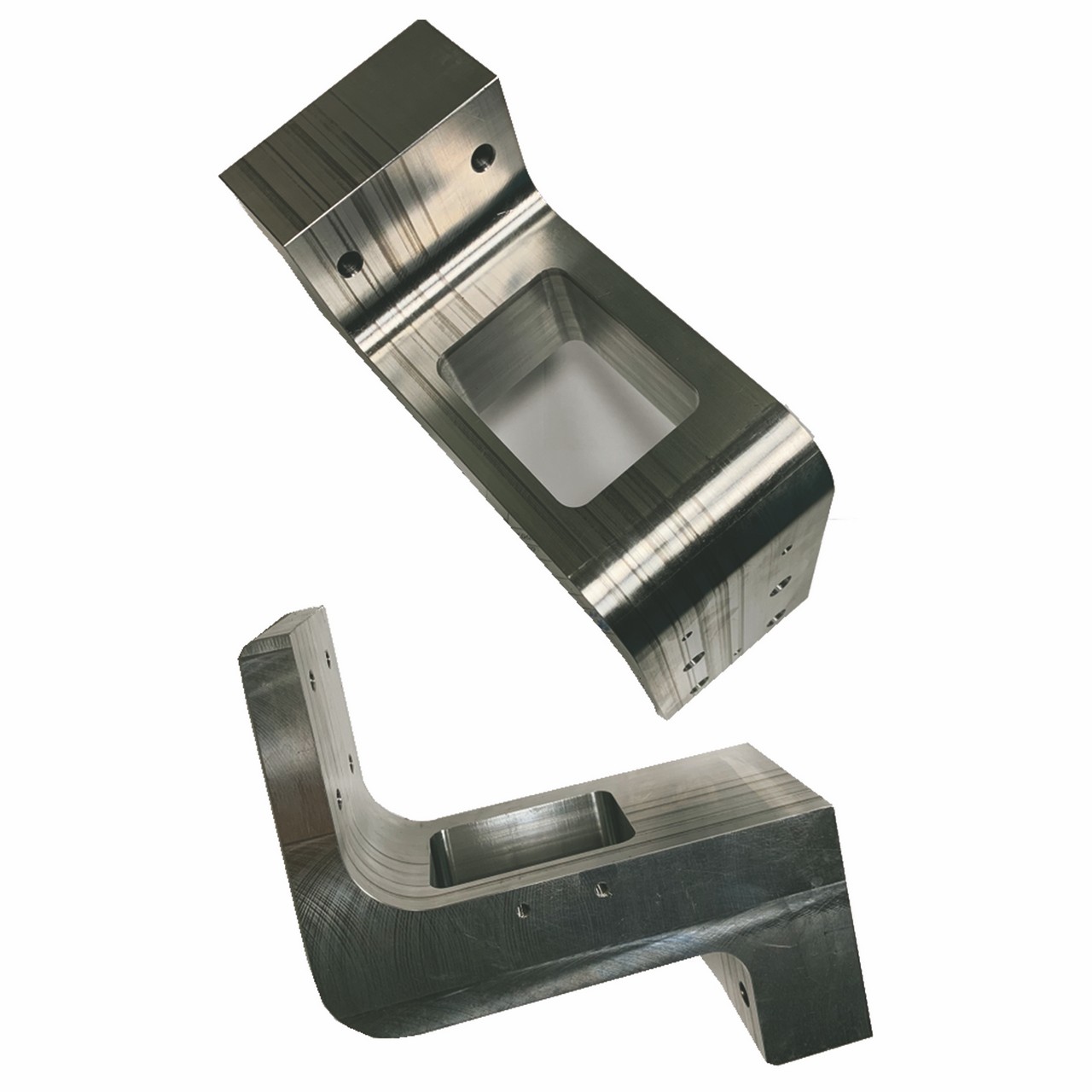

cnc machined metal part

COMPUTER NUMERICAL CONTROL Machining is a subtractive manufacturing method that uses trimming tools to remove material from a block of natural material or a pre-existing part.

Capability = Velocity

Our own capacity permits all of us to create COMPUTER NUMERICAL CONTROL machined parts with unrivaled speed.

In the same time, our experienced technicians ensure the greatest requirements with innovative software and equipment.

Capability = Range

All of us operate more than 20 state-of-the-art engineering centers with a wide variety of CNC equipment such as single axis lathes.

Single axis lathes are perfect for executing round components such as valve, engine components and thread shafts.

Our own CNC machining facilities also utilize trimming edge 5-axis machines, which substantially reduce turnaround time by reducing intermediate setups and enabling undercuts and off-axis features.

COMPUTER NUMERICAL CONTROL Machining Is Supporting Technology

We also utilize CNC Engineering as a valuable secondary procedure for our 3D imprinted parts that need dull, drilling, face milling or other accuracy machining for improving features.

We have been dedicated to providing the speediest CNC engineering in the industry, with projects developed and started the same day as order.

Precise Concluding for Cnc-machined Elements

We give you a variety of expertly applied finishing options to enhance the mechanical and aesthetic properties of your CNC machine component, including piece of art, anodizing, EMI and RFI shielding and hand polishing.

COMPUTER NUMERICAL CONTROL Machining Supplies

Satisfy your most strenuous and precise apps with CNC materials. We can machine almost any executive material, including plastic materials, metals, alloys, and foam or pedaling board.

Plastic Supplies for CNC Executive

Material

Description Benefits Applications Properties

AB MUSCLES

Low cost executive plastic that is not hard to machine and fabricate

Excellent impact opposition

Good machinability

Excellent aesthetic features

Simple to paint and stuff

Good power and stiffness

Reduced cost

Machined representative models

Structural components

Assistance blocks

Enclosures

Includes

Contact an Professional

Polycarbonate

Engineering plastic-type with excellent dimensional stability and good strength and tightness over an array of service temperatures.

Low humidity absorption

Good insulation properties

Excellent flammability rating

Simple to fabricate, paint and stuff

Structural applications demanding clarity and impact strength including contacts, manifolds, site eyeglasses and machine pads

Electrical apps

Make contact with an Professional

Polycarbonate 20% FRIEND

twenty percent glass reinforced polycarbonate with higher temp and tensile properties.

Superior impact power

Excellent dimensional stableness

Outstanding mechanical power and tightness

Openness

Good electrical properties

Good machinability

Things, rollers, internal mechanised parts, connectors and relays

Pumps, regulators, light bezels and instrument solar panels

Make contact with an Professional

Synthetic 6/6

Type 6/6 is an over-all objective, standard grade synthetic. Extruded in natural and black.

Excellent wear opposition

Reduced frictional properties

Extremely good temperature, chemical substance and impact properties

Ideal for steel replacement applications such as:

Bearings

Things

Sheaves

Sprockets

Make contact with an Engineer

thirty percent GF Nylon

thirty percent glass-fiber reinforced synthetic 6/6 material with superior abrasion and wear resistance.

A lot more than double the strength and tightness of unreinforced extruded nylons

Heat deviation temperature approaches their melting point

-

Contact an Professional

Delrin

Crystalline plastic-type that offers a fantastic balance of properties that bridge the gap between alloys and plastics

Very good dimensional stability

Superb machinability

Superior impact and creep opposition

High fatigue stamina

High strength and stiffness properties

Chemical substance resistance from fuels and solvents

Low humidity intake

Good wear and abrasion properties

Well suited for many business wear and mechanised apps

Parts revealed to a damp or wet atmosphere, such as water pump and valve components

Gears

Bearings

Bushing

Rollers

Fixtures

Power insulator elements

Make contact with an Professional

HDPE

HDPE can be used in a wide variety of applications and industries where excellent impact resistance, high tensile strength, low moisture absorption and chemical and deterioration resistance properties are essential.

Meets FDA/USDA food handling guidelines (natural color)

Chemical- and corrosion-resistant

Light-weight

Zero moisture absorption

Large tensile strength

Non-toxic

Non-staining

Thermoforming performance

Ligh-duty chain instructions

Orthotic and prosthetic devices

Secondary hold

Reservoirs

Thermoformed substance handling devices

Drinking water safe-keeping

Contact an Professional

Polypropylene

Transparent material noted for its high strength-to-weight ratio, excellent chemical substance resistance and high performance in thermoforming and corrosive conditions

Appropriate for apps to 180F (82C)

Resists most stomach acids, alkalis and solvents

Meets FDA 21CFR 177. 1520

Thermoforming performance

Chemical- and corrosion resistant

No humidity intake

Meets UNITED STATES DEPARTMENT OF AGRICULTURE guidelines for use in federally checked out meat and chicken packing facilities

Orthotic and prosthetic devices

Plenums and manifolds

Secondary containment

Control device bodies

Plating and anodizing process equipment

Pump components

Safe-keeping tanks

Contact an Engineer

Clear Polymer-bonded

Rigid, hard thermosoftening plastic material that is characterized by their color range supply and straightforward fabrication

Superb UV stability

Indication make

Point of Sales display devices

Safety glazing

Device enclosures

Model make

Contact an Professional

PVC

Normal impact, high corrosion tolerant polyvinyl chloride

Large strength-to-weight proportion

Price efficiency

Simplicity of manufacture

Economic balance

Essentially suited for apps where maximum chemical substance resistance is necessary

Contact an Professional

ULTEM 1000 Botanical

Amorphous thermoplastic polyetherimide (PEI) material that combines exceptional mechanised, thermal and power properties; Natural ULTEM 1000 Resin (unreinforced) is a clear amber material

Superb mechanical strength

Excellent heat resistance

Excellent resistance from environmental makes

Inherent flame opposition with low fumes advancement

Medical

Electronic/Electrical

Micro wave

Automobile

Aircraft

Contact an Engineer

ULTEM a thousand 20% GF Botanical

Addition of a glass fiber reinforcement to the basic ULTEM Resin

Greater ultimate tensile strength and rigidity

Increased dimensional stability

Health care

Electronic/Electrical

Microwave

Automobile

Aircraft

Contact an Engineer

G-10 FR4

Versatile, all-around electrically insulating material

Epoxy impregnated laminate which meets UL94-V0 requirements

Can be precision machined or die-cut to meet any custom requirements

-

Make contact with an Engineer

Steel Materials for COMPUTER NUMERICAL CONTROL Engineering

Material

Description Benefits Applications Properties

Aluminum 6061 T6

Generally selected where welding or brazing is necessary or for its high deterioration resistance in every emotions; Machining is far more difficult when compared to the other engineering alloys

Formability is excellent in Um temper and good at the T4 state of mind

Corrosion opposition and look after anodizing are superior to all other screw machine metals while strength is the best

-

Make contact with an Engineer

Light weight aluminum 7075 T6

Primary 7XXX alloy with a good balance of properties necessary for aerospace apps

First successful Al-Zn-Mg-Cu hi-strength alloy using the beneficial results of the alloying addition of chrome to develop good stress-corrosion cracking opposition in sheet products

Aircraft and tail wind structures

Alclad epidermis sheet

Structural platter components up to 4 inches thicker

General aluminum tail wind applications

Contact an Engineer

Mic six

Similar to those in the 7000 series with accurate adaptable additions of Zinc, Copper, Magnesium (mg) and components of Silicon, Iron and Manganese

Light-weight

Clean flatness threshold

Very good machining features

Free of charge from tension, pollutants and porosity

Device components

Aerospace and automotive components

Electronic devices

Laser technology and optical industry

Make contact with an Engineer

303 Stainless Steel

Austenitic free-machining stainless stainlesss steel used mostly for parts requiring engineering, grinding or perfecting

Good corrosion opposition in mild conditions

Good forming properties

Aircraft apps

Device parts

Pump and valve elements

New applications

Nuts and bolts

Contact an Engineer

Mild Stainlesss steel

- - - -

Stainless-steel

- - - -

Tool Stainlesss steel

- - - -

Get a Estimate

Ready to make your spend COMPUTER NUMERICAL CONTROL Machining Upload your CAD file now to select your material and create an instant estimate.

Get Design Providers

Need some help with your 3 DIMENSIONAL design Our design services team supplies a suite of remedies, including file design and file repair.

Use Material Sorcerer

Want to compare CNC material properties Use our substance wizard to learn which materials meet your part's requirements.

COMPUTER NUMERICAL CONTROL Machining Applications

computer numerical control machining production elements

PRODUCTION PARTS

Fabricate highly accurate, large production parts with CNC machining.

Reading more

cnc machining lures & fixtures

LURES & FIXTURES

Include value to the availability floor with highly accurate precision machined manufacturing aids.

Study More

cnc engineering functional representative models

FUNCTIONAL PROTOTYPES

Make use of CNC machining to generate prototypes in your production material for functional testing.

Reading more

How Much Really does CNC Machining Knowledge Matter

a producing production floor with cnc machinesMaking a quality part will take more than simply a machine.

It will take a responsive team right behind the technology, working tests and working tirelessly to confirm materials and techniques.