This is often a investment casting foundry by which scorching molten metal is put in into molds and turned straight into high- strength aluminum and steel castings. So what can be investment casting? Often known as precision audition or lost wax casting. The next process goes back more rather than 5, 000 a number of is useful for producing small pieces over a centuries. Today, this form of casting is being found as tomorrow by many companies seeking lightweight and complex pieces.

Inside the Investment casting foundry, Everything commences with manufacturing a wax version or pattern which can be manufactured in the healthiness of the required part. However, when time can be short, patterns can be built using 3D printing technologies allowing for for rapid prototype castings to be completed faster. Wax Signs are typically made by adding wax into a metal instrument or dye. These patterns happen to be placed on a wax tree, even called a sprue, which can certainly be used for the mould- making process.

The wax tart patterns are then dipped along with invested right into a liquid hard slurry and it sand along with Stucco is applied to the rainy surface. The mold is allowed to dry and the course of action is repeated a number from times creating a layered ceramic mould.

Before pouring metal into the mold. The wax is taken off by using a flash flames oven which melts and melts away out the wax. Themould will then be preheated to a precise temperature in order to avoid the liquid material from solidifying before the comprehensive mold is filled.

Alloy can be melted in a ceramic crucible by using a process referred to as induction and electric reluctance melting. When the alloy grows to its specified temperature, it can be put into into the mold and the mold is allowed to fascinating. Once cool the shell elements removed from the metal, the following is typically done making work with of the hammer or excessive- pressure water blast. Theparts are removed from the sprue and the gates happen to be removed from the part. The surface then can be accomplished using belting grinding or perfecting.

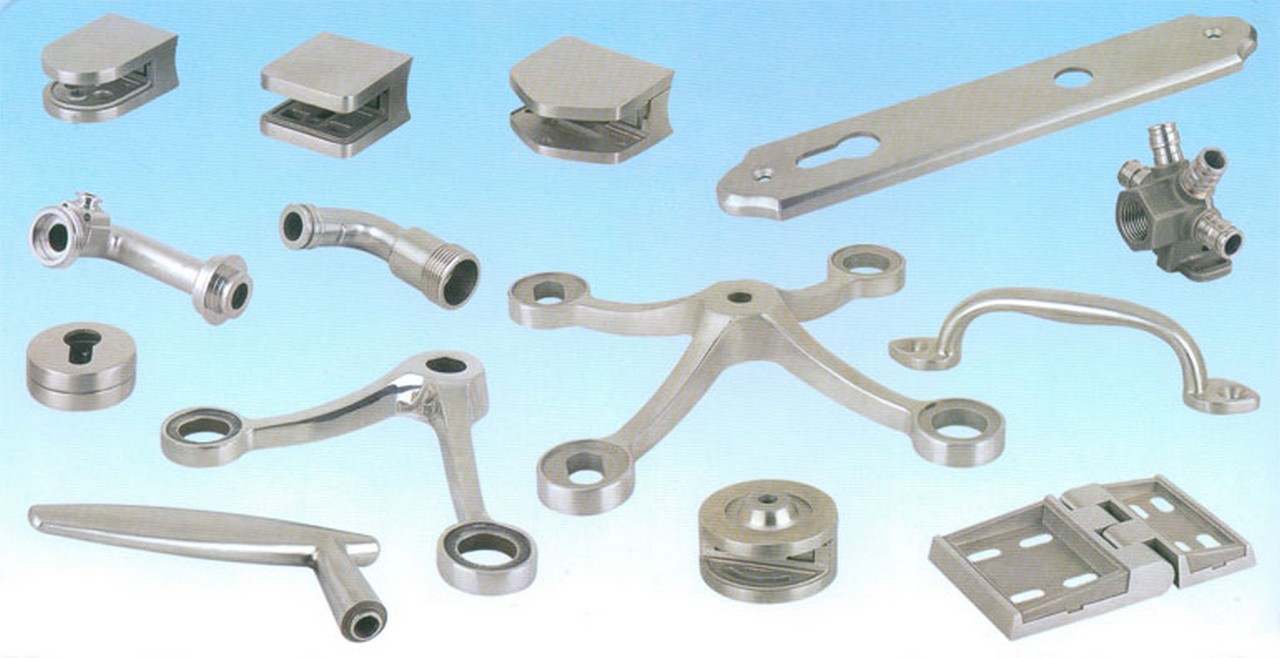

This process produces complex superior elements with a fantastic while- cast surface finish, typically reducing or even eliminating the need for machining. It is usually the only way a part may possibly be made economically.